Spare Parts and After Sales

Promill offers a number of preventive maintenance options, each of which can be customized to your plant maintenance strategy.

We may refer on more than sixty years of experience and satisfied customer in drying, rotating, drums, cylinder, crusher, milling and pelleting equipment.

Optimized performance

Promill preventive maintenance agreements are customized to individual customer needs, depending on supplied plant and equipment.

You can choose between a variety of service options within an time period, discounted spare parts packages, technical support, consultancy services, and recommendation of wear parts in reasonable number in local inventory.

The first step towards the right result

The first step is to discuss your needs with us, and identify the relevant service and maintenance solutions for your Dryers, Rotating drums, Hammermills, Cylinder crushers, and Pelletizers and other process operations.

The result is the operational assurance you need in the right scope.

Benefits

A preventive maintenance agreement with Promill means:

Avoiding unscheduled downtime

Optimizing throughput

Reduction energy costs

Maintaining constant product quality

Compliance with environmental and safety standards

The best qualified specialists for specific needs

A high durability and reliability of capital goods and plants win further in importance.

However nothing lasts forever and in order to avoid long standstill periods on reason of non available parts.

This leads in majority of cases to increased costs.

We may offer support for establishing a reasonable spare parts stock locally.

On-site spares

While the cost of a predicable downtime are calculable, so may not justify extra cost of air freight, you can save extra time and money by maintaining a stock of the most important parts locally.

This means to considering to question in order to avoid unnecessary downtimes, with a tying up a minimum of capital in spares.

Promill Spare Parts service enables you to optimize your production by:

- Availability of vital spares quickly in an emergency

- Maintaining a local stock to ensure readiness at acceptable cost

- Obtaining parts for older plant by separate order

These services are also available as part of a preventive maintenance agreement customised to your needs.

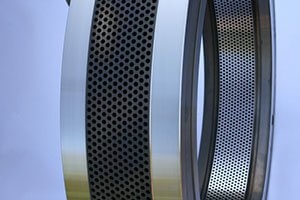

Parts refurbishing

PROMILL has a service specialized in the repair of components.

We propose to our customers a study followed by a project to recondition the pellet mills and hammer mills components.

Troubleshooting

Occasionally problems can arise whose cause is not immediately apparent. These problems rarely bring production to a complete halt, but they can have a serious impact on profitability or customer satisfaction if they are allowed to persevere.

Getting you back up to speed

Many years of experience in a wide variety of plant and applications mean that a Promill specialist will invariably find the cause of a problem in a very short time.

n most cases, it can be rectified on the spot. Operators are involved and learn how to avoid the problem in the future. You can contact our engineers by phone, fax or e-mail.

And if your plant is remotely monitored, you may even hear from us before you realize that anything is wrong !

Benefits

Troubleshooting means:

Rapid return to normal operation and profitability

Operator awareness of how to avoid the problem in the future

Training

Training by Promill provides the customers with know-how about process technology for machines and plant; either to sensitize the employees in the shop floor for working with this technology, or to refresh existing knowledge in a common training.